Do you need accurate filtration? If yes, then you need to have the basic concept of a sintered filter disc. What is worth appreciating is that sintered filter media is strong. It can be used to filter plastic melt with a large filter area, usually working in high pressure and high temperature environment.

Now, we will go through the concept of a sintered filter disc in detail to get essential insight.

What is a Sintered Disc Filter ?

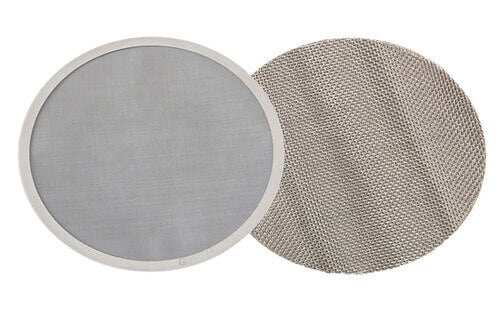

Well, the sintered disc filter can get termed as an ideal element for the process of filtration. The disc gets made using sintered wire mesh by utilizing laser cutting. Sintering can get termed as a process that produces fusion bonds at every contact point of a woven wire mesh. The fusion bonds get produced in a vacuum environment at a very high temperature.

Benefits of sintering

The benefit of sintering is that it tends to maintain the uniformity of the original weave. Secondly, sintering also fixes the micron rating, shape and hole size of the mesh. The sintered wire mesh is multilayered.

The multilayering supports rigidity and high strength. The filter discs get used for different purposes. As a result, they get processed in different shapes. You will come across fan-shaped, oval, square or round filter disc.

Types of Sintered Disk Filter

The sintered disk filter can get added to outer rings too. The sintered disk filter can get classified according to the material type. You will come across the following types of filter discs:

- Metal Mesh filter discs

- Polymer leaf disc filters

- Pleated filter disc

- Sintered powder filter discs

The stainless steel wire mesh filter disc is the most popular among the available varieties. It is made using stainless steel mesh and it gets cut by the laser machine.

When you make use of a filter disc, then it will not be difficult for you to ascertain the quality of filtration. The reason is that filter discs are color-coded to indicate the filtration level. When you can acquire clean liquid, then this indicates high quality filtration.

Advantages of using sintered disc filter

- The sintered metal wire mesh filter disc has a variety of advantages:

- You can look forward to a long service life with sintered disc filters.

- They have a perfect dirt holding capacity.

- The disc has high heat resistance.

- The sintered disc filters offer great precision for a variety of uses.

- They are resistant to acid, alkali, abrasion, and corrosion

The good news is that the disc filters are quite easy to clean. The benefit of this practice is that you will not have to worry about downtime.

Sintered Metal Filter Disc Type Selection

Metal Mesh filter discs

If you want to go for metal mesh filter discs, then the good news is that Metal Mesh filter discs can get custom made. Multi-layer woven mesh or single deck gets parceled in aluminum conjugates. The frame package of the metal mesh filter disc looks rigid.

The metal mesh filter discs are airtight and consistent. The objective of the metal mesh filter disc is to provide filter protection to gas flow and liquid systems. The best part is that metal mesh filter discs are affordable.

These filter discs can work well with a variety of fluids with varying temperatures. For example, these discs get used at a temperature between 270 to 450 degrees centigrade. These discs can accommodate a pressure of about 3 bar.

There are two types of metal mesh filter discs. You can go for unrimmed or rimmed ones.

Polymer leaf disc filters

Usually, the Polymer leaf disc filters get used for the recycling of catalysts. They also get used for the filtration of hot melt polymers. The benefit of these filter discs is that they offer smooth flow and it becomes easy to achieve gel control on the filter.

When you go for quality polymer leaf disc filters then you can look forward to long service life. The disc has a firm structure so that you can look forward to a clean cycle. As a result, lifetime costs get reduced.

The Polymer leaf disc filters make use of composite material and utilize sintered woven wire meshes.

Pleated filter disc

Well, the pleated filter gets produced using woven wire meshes having multilayer precision. The pleated filter disc is precisely stamped and laser cut. You can look forward to high processing quality because of the cut.

The rimmed pleated filter forms a tiny seal at the front of the flange present between the discs. As a result, it becomes easy to install the rimmed steel filter.

Sintered powder filter discs

You can also go for sintered powder filter discs. The benefit of these discs is that they have a wide range of thicknesses. These discs are available in a variety of micron sizes. The best part is that the discs have a high shear resistance.

How to Choose the Sintered Filter Disc?

There are various aspects you should consider when you have to choose a filter disc.

Should be compatible with the liquid

The essential aspect is that the sintered filter disc should be compatible with the liquid that you wish to filter. When the liquid is compatible, you will not have to worry about the reaction between the liquid and the filter disc.

Consider the mesh size and mesh number

When you choose a filter disc for the process of filtration, then the mesh size also matters. The mesh size refers to the holes present on the mesh. Another aspect you need to consider when choosing your filter disc is the mesh number. The mesh number refers to the number of holes present on the mesh filter.

You should not ignore the strand diameters when choosing a filter disc. There are times when the wire has a broad strand diameter. Well, this means that the mesh has tiny holes.

Every filtration media has a set of advantages and disadvantages. Choose the filter disc with the appropriate filtration media.

How do Sintered Filter Discs Get Manufactured?

It is essential to test the quality of materials before the production of the sintered filter disc. For example, you need to determine the type of stainless steel that will get used for disc production. It is used to test different layer groups of sintered wire mesh disc media.

It is composed of multiple layers of metal wire braided mesh, and can be made into a composite metal wire mesh porous material after high temperature sintering. According to different installation size requirements, different size types are cut by laser and water jet. The quality of the disc filter also needs to be tested to ensure that it lives up to the standards.

How does sintered filter disc work?

The fluid tends to flow into the filter through the filter inlet. The filter lamination tends to get pressed tightly due to the action of the spring force. The impurity particles get trapped in the lamination cross. The clean liquid flows out through the filter’s main channel.

Key Features of Sintered Filter Disc

Exclusive backwashing

The filter disc follows the specific principle of backwashing. When a specific pressure difference is reached, the controller controls the valve to open. After the set time, the valve flap may also enter the backwash state.

When disc acquires the backwashing stage, the one-way diaphragm present at the bottom of the filter closes the main channel. The jetting is in the tangential direction of the lamination. As a result, the spray water gets sprayed over the surface of the lamination. The impurities present on the lamination get ejected.

After the backwash is completed, the water flow shut-off valve is closed and the system tends to re-enter the filtration state. The exciting part is that the backwashing process of the sintered filter disc is automatic.

The working and the backwashing state get switched automatically. The benefit of this practice is that you can look forward to continuous water discharge. The best part is that high speed backwashing can get done at a very high speed.

Precise and efficient

What you will appreciate about filter disc is that it is efficient and precise. The filter disc offers sensitive performance. You can choose your filter discs depending upon your flow requirement.

Can Sintered Stainless Steel Filter Discs be Cleaned?

There are various processes that you can adopt for cleaning stainless steel filter disc. When you want to clean the disc, then the simplest process is to soak and flush the disc. For this, you will need to make use of a detergent solution.

You will need to soak your disc in the detergent solution so that you can loosen the particles.

You can also clean the filter discs through the process of furnace cleaning. The process involves burning biological compounds for cleaning the filter disc. The method works well when you need to remove polymer materials.

You can also clean the filter disc through the process of circulation flow. Now, a cleaning system is a dire need for circulation flow. You will need a cleaning solution that can pump the cleaning solution through the filter mesh.

Ultrasonic baths are also useful when you need to clean your filter disc. The ultrasonic waves tend to trigger off the particles and they get removed from the filter mesh.

There are times when particles badly block the filter mesh. In this case, you will need to use hydro blasting method for cleaning your filter disc. High pressure water jet gets used in this situation. It removes the trapped particles from the filter mesh without a problem.

What are the Installation Methods of Sintered Stainless-Steel Filter Discs?

The good news is that installing a sintered stainless-steel filter is not a difficult job by any means. You can even install the filter disc on your own. However, it is essential that you follow the installation guide.

The best approach is that you should have a checklist to install the filter disc. You will need tools for opening the housing of the filter disc. Make sure that you open up the casing of the filter disc housing. For that, you will need to free the holding clamp.

It is also essential to pull out the tightening cylinder and next you will need to install the filter disc.

Next, return in the position of the tightening cylinder. You will also need to fasten the butterfly nuts that clasp your filter disc. Do not forget to replace the top casing of your filter housing. In the end fasten the holding clamp.

What are the Applications of Sintered Filter Discs?

Filter disc sintered get used for the filtration of corrosive liquids. The filter discs also get used for catalyst recovery. Plus, the filter disc can get utilized for steam processing also. Secondly, the disc filter has usage in different types of industries.

- Aviation industry

- Chemical industry

- Petrochemical industry

- Environmental area

- Automotive industry

- Plastic industry

- Food and Beverage industry

Conclusion

You can invest in a sintered filter disc with confidence because it guarantees accurate filtration because of the gauge mesh. The mesh can trap the particles and this is why you can look forward to superior filtration quality.

Before buying a filter disc, make sure that you choose the best manufacturer. It will be viable to shortlist the best option. The benefit of this practice is that you will be able to choose a quality filter disc without a problem.