Media Filter

When it comes to the separation of suspended pollutants, the best way is to start the process with a strainer. Media filter is a kind of high-efficiency filtration equipment which uses media filter to remove mechanical impurities, colloids, organic matters and active chlorine in water, and finally achieves the effect of reducing water turbidity and purifying water quality.

Types of Strainer

- Temporary Strainers

- Permanent Strainers

Permanent Strainers

- T-type strainers

- Y-type strainers

- Basket strainers

- Duplex or multiple strainers

- Self-cleaning strainers

Temporary Strainers

- Cone Type Strainers

This article will introduce the characteristics and application scope of each strainer so that you can choose the most effective medium filtration mode in different use environments.

Temporary Strainer

Cone Type Strainers

Industrial conical strainer are the simplest filter form of pipeline coarse filter series, which can remove large solid impurities in the fluid when installed on the pipeline so that the machine and equipment (including compressor, pump, etc.) can work and operate normally, achieve stable process, and ensure the role of safe production.

When the fluid enters the filter cartridge with a certain size of the filter screen, its impurities are blocked, and the clean filtrate is discharged from the filter outlet. When it needs to be cleaned, just take out the removable filter cartridge and put it in again after treatment. Therefore, it is very convenient to use and maintain.

Where is The Cone Strainer Mainly Used?

Temporary cone strainer are mainly used for steam, water, oil or natural gas and are installed between two flanges to protect downstream equipment. Temporary conical strainer are either used temporarily or at the most important cost. In particular, install the tapered filter with the top facing the flow direction.

Permanent Strainers

T-type Strainers

The shape of the T-type strainer is like the letter "t", so we call it T-type strainer. The T-type strainer made of stainless steel perforated plate or metal mesh supported by a perforated plate is small equipment to remove a small number of solid particles in the liquid.

Its unique design of the rotary filter screen doubles the screen area and completely changes the dirt accumulation mode on the screen. It can not only make more efficient use of the filter area of the screen but also reduce the cleaning frequency.

The swirling filter screen and unrestricted flow path can make the pressure drop to a very low level, which is an ideal solution for applications such as condensate and boiler feed pump extraction (with good water quality and high-pressure drop requirements).

Where is The T-type Strainer Mainly Used?

T-type strainer is usually used to protect pumps or other applications with low solid particle content, which has many advantages over other pipeline filter designs. The compact design is ideal for applications with limited space, either vertical or horizontal, and eliminates the need to empty the container when cleaning the pipe filter. It is also suitable for direct current or right angle current applications and is very suitable for retrofitting.

Y-type Strainers

The Y-type strainer is designed to protect downstream process system components by mechanically removing unwanted solid particles from liquid, gas, or steam lines through a perforated or wire mesh filter element.

To avoid side flow, the Y-type strainer is equipped with a finely processed screen seat, and the strainer is equipped with a high-quality stainless steel screen that can perfectly fit the pipe filter body. The Y-type strainer is available in carbon steel or stainless steel. The applicable pipe size ranges from 1 / 4 "to 10. It is connected by thread, flange or socket welding.

TheY-type strainer is a cost-effective filtration solution in situations where the amount of material removed from the fluid is relatively small (resulting in a long separation between screen cleaners). When cleaning the filter screen, it is necessary to close the pipeline and remove the pipeline filter cover for manual cleaning.

For applications with heavy dirt loads, a "drain" connection can be fitted to the Y-type strainer, which can be cleaned without removing the screen from the pipe filter body.

Where is The Y-type Strainer Mainly Used?

Y-type strainers are typically used in applications where the number of solids to be removed is small and where frequent clean-out is not required. They are most often installed in gaseous services such as steam, air, nitrogen or natural gas. They can be used in both vertical and horizontal installations.

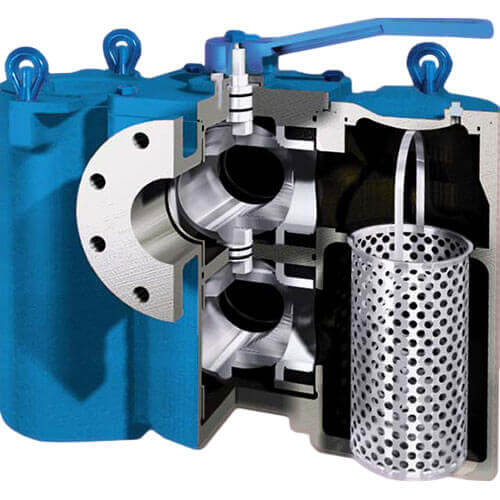

Basket Strainers

Basket strainers straight flow design, low-pressure loss, perforated hole diameter of basket is 1 / 32 "to 1", suitable for 20 to 400 mesh lining of fine filtration application.

Where is The Basket Strainer Mainly Used?

Basket strainersare commonly used in applications where larger particulates are present and require frequent clean-outs. Basket strainers offer top removal of the internal screen. The internal perforated basket features a handle at the top for easy removal and disposal of all the particulate that is collected.

The basket strainer consists of aduplex basket strainer that operates continuously and two basket housings are connected by a valve diverter. When the basket in the first housing is fully loaded, the butterfly valve assembly can be easily used to switch the fluid to the second. At this time, the first basket can be removed, cleaned or replaced for reuse, and the pipe does not need to be closed.

Duplex or Multiple Strainers

Duplex or multiple strainers is composed of two or more single cartridge filters and two positions six-way reversing valve, which is simple in structure and convenient in use, with bypass valve and filter element pollution blocking transmitter, so as to ensure the safety of the system.

Duplex or multiple strainers are made of perforated plates or wire mesh and are best suited to remove particles smaller than 40 microns. Its advantage is that it can be cleaned and reused by hand frequently. In addition, carbon filters are also valuable in the treatment of feed water containing organics, pesticides or chlorinated compounds.

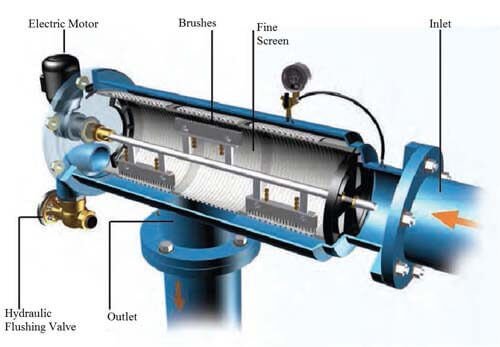

Automatic Backwash Water Filter Industrial use

The auto backwash water filter is mainly used for purifying water. It can be used in industry, agriculture, power, electronics, medicine, food, printing and dyeing, construction, steel, metallurgy, paper making, coal mine, swimming pool, landscape, greening, and other industries, especially in the microfiltration field with high requirements for water quality.

Auto clean water filter has many functions to remove sediment and viscosity in water Impurities such as soil, rust, suspended solids, algae, biological slime, corrosion products, macromolecular bacteria, organics, and other small particles can achieve the purpose of water purification.

Summary

The above is the characteristics and application scope of each water filters for industrial applications. I hope you can choose the most effective media filtering method in different use environments.

If you have any questions about industrial water system filtration, please leave a message in the comment area and we will reply in time.